PROTOTYPE DEVELOPMENT

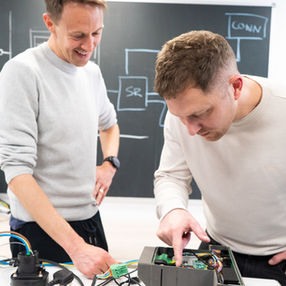

Prototype development is crucial to the new product development journey. Our in house prototyping design services allow us to efficiently test and iterate concepts throughout a project, transforming designs into practical solutions and enhancing speed to market for our clients.

Utilising cutting-edge 3D computer aided design software or team can produce anything from proof-of-concept test rigs to high-quality working prototypes.

PRODUCT PROTOTYPING SERVICES

PROOF OF CONCEPT PROTOTYPES

Proof of concept prototypes allow the principles and basic functionality of a design to be evaluated before further work is carried out. Proof of concept prototypes range from handheld models to evaluate form, key controls and touch points; to larger electromechanical equipment to integrate Electronics, check motors and refine mechanisms. Testing and iterative improvement of proof of concept prototypes is a valuable step in the design process to help understand how users will interact with the product, whether features and mechanisms will work correctly and potential failure points.

PRESENTATION PROTOTYPES

As the design is refined, we can manufacture presentation grade prototypes to give a top-quality representation of the final functionality, materials and appearance of your product.

Pre-production prototypes can be created using prototyping techniques such as CNC machining and Vacuum Casting or even prototype aluminium production tooling. These prototyping processes alongside high quality materials and finishes deliver high quality prototypes that reflect production intent. Which are vital tools to present your idea to investors for further Funding.

IN HOUSE RAPID PROTOTYPING

Our in-house rapid prototype design services include 3D printing prototypes, SLS/SLA, CNC Machining & Vacuum Casting.

These rapid prototyping techniques are used throughout our development process, to manufacture prototypes quickly and allow development prototypes to be created to test and refine your product design quickly and cost effectively, delivering the best possible design outcome to clients.

High quality prototypes are an important step to validate your product idea, before investing in Manufacturing.

CONTACT US ABOUT

CREATING A PRODUCT PROTOTYPE

GET A QUOTE

NEXT STEP - ELECTRONIC DEVELOPMENT

PRODUCT DESIGN SERVICES

VIEW OUR WORK

CONCEPT DEVELOPMENT FAQs

What is prototyping?

Prototyping is a vital step in developing and validating product concepts, functionality, and design. At Duku, we offer a range of prototyping design services to bring ideas to life—enabling us to test, evaluate, and refine models to ensure the highest standards of innovation and usability. Our iterative process helps identify potential issues early, optimise designs, and streamline the path to manufacturing.

What is 3D printing?

3D printing is a process of creating three-dimensional objects by layering materials. 3D printing is an additive process whereby layers of material are built up to create a 3D part. 3D printing can be a quick and cost-effective way to produce prototypes or low volumes of products.

Why is prototype development important?

Prototype development is a crucial phase in your product design project at Duku because it allows us to transform concepts into tangible, testable models. By creating product prototypes, we can identify potential design flaws early, ensure the product meets user needs, and test functionality. This iterative process of designing, prototyping, and refining helps save both time and cost by addressing issues before full-scale manufacturing begins.

How do I make a prototype of my idea?

First, we will guide you through new product development stages, including concept development and CAD design. Once the design is ready, we use a range of prototyping techniques—such as 3D printing, vacuum casting, CNC machining, and metalwork—to produce a functional prototype tailored to your project’s needs.

How many prototypes do I need before manufacture?

Prototyping is as important as concept design for exploring and refining ideas for manufacture. While simpler products may be developed within a single prototype development stage, more complex designs often require multiple iterations to achieve the best results. When you request a quote, we’ll provide a bespoke plan outlining the costs and next steps tailored to your project.

How much does it cost to make a prototype

The cost to create a prototype can vary depending on the complexity, materials and specific requirements of your product. Generally, our prototype design services range from a few hundred pounds for simple 3D-printed models to several thousand pounds for more intricate designs involving advanced manufacturing processes.